I stand by Yetter Devastators

"I stand by #yetter #devastators Great product

"

612C

616C

4412

Drago Series

On Header Cart

Loading Header Cart

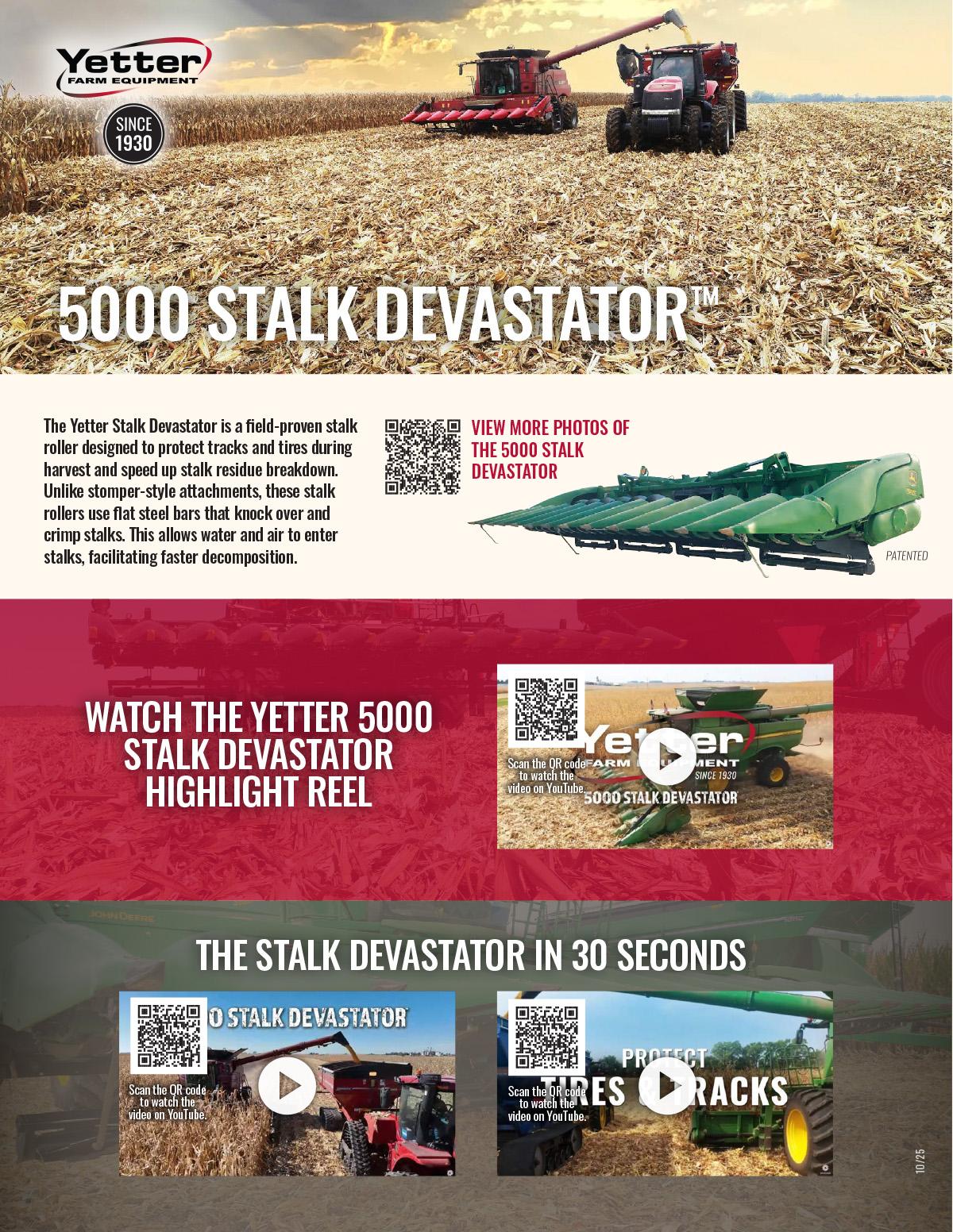

Today’s hybrids develop tough stalks that can destroy expensive tires and tracks on equipment. The 5000 Stalk Devastator™ saves tires and tracks by knocking over and crimping stalks while leaving them attached, speeding up the cornstalk breakdown process and improving field conditions for spring planting.

Features:

*Patented

Specs:

Product Focus Page

Beck's included the Yetter 5000 Stalk Devastator in a study of the payoff timeframe for corn head residue management tools during harvest.

|

Devastator Model No. |

Description |

Corn Head Model |

Devastator Type |

Est. Weight |

|

CASE IH |

||||

|---|---|---|---|---|

|

5000-013B |

6-Row |

1063 |

Compression Spring |

657 lbs. |

|

5000-005B^ |

6-Row |

3206/ 3406 |

Compression Spring |

657 lbs. |

|

5000-014C |

8-Row |

1083 |

Compression Spring |

922 lbs. |

|

5000-006C^ |

8-Row |

3208/3408 |

Compression Spring |

960 lbs. |

|

5000-019C^ |

12-Row |

2412/3412 |

Compression Spring |

1,317 lbs. |

|

5000-036^ |

8-Row |

4408, Folding |

Compression Spring |

1,017 lbs. |

|

5000-042D-CNH |

12-Row |

2212/2412/3212/3412, Rigid Corn Metering |

Torsion Pivot |

725 lbs. |

|

5000-046D-CNH |

12-Row |

2212/2412/3212/3412, Rigid |

Torsion Pivot |

650 lbs. |

|

5000-060E |

6-Row |

2606/4206/4406 Chopping, Rigid |

Torsion Pivot |

490 lbs. |

|

5000-061E |

8-Row |

2608/4208/4408 Chopping, Rigid |

Torsion Pivot |

652 lbs. |

|

5000-062E |

12-Row |

2612/4412/4412F Chopping, Rigid and Folding |

Torsion Pivot |

932 lbs. |

|

5000-063E |

12-Row |

4412 Chopping, Rigid |

Torsion Pivot |

722 lbs. |

|

CHALLENGER |

||||

|

5000-023C^ |

6-Row |

CH630 |

Compression Spring |

767 lbs. |

|

5000-024C^ |

8-Row |

CH830 |

Compression Spring |

1,047 lbs. |

|

DRAGO |

||||

|

5000-007D |

6-row |

630 Series I and II |

Compression Spring |

682 lbs. |

|

5000-017D |

8-Row |

830 Series I and II |

Compression Spring |

922 lbs. |

|

5000-018D |

12-Row |

1230 Series I and II |

Compression Spring |

1,307 lbs. |

|

5000-050E |

6-Row |

6R30 Drago GT (Non-chopping head) |

Torsion Pivot |

597 lbs. |

|

5000-051E |

8-Row |

8R30 Drago GT (Non-chopping head) |

Torsion Pivot |

827 lbs. |

|

5000-052E |

12-Row |

12R30 Drago GT, Rigid and Folding (Non-chopping head) |

Torsion Pivot |

1,037 lbs. |

|

5000-053D |

16-Row |

16R30 Drago GT (Non-chopping head) |

Torsion Pivot |

1,600 lbs. |

|

5000-054C |

18-Row |

18R20 Drago GT |

Torsion Pivot |

990 lbs. |

|

5000-055C |

18-Row |

18R22 Drago GT |

Torsion Pivot |

1,050 lbs. |

|

5000-056B |

12-Row |

12R20 Drago GT |

Torsion Pivot |

863 lbs. |

|

FANTINI |

||||

|

5000-031C |

8-Row |

8R30 Fantini |

Compression Spring |

1,070 lbs. |

|

GERINGHOFF |

||||

|

5000-040C-GER |

6-Row |

6R30 Geringhoff (all models except Freedom) |

Torsion Pivot |

592 lbs. |

|

5000-041C-GER |

8-Row |

8R30 Geringhoff (all models except Freedom) |

Torsion Pivot |

772 lbs. |

|

5000-042C-GER |

12-Row |

12R20 Geringhoff (all models except Freedom) |

Torsion Pivot |

812 lbs. |

|

5000-044C-GER |

12-Row |

12R30 Geringhoff (all models except Freedom), Rigid and Folding |

Torsion Pivot |

1,052 lbs. |

|

5000-045C-GER |

18-Row |

18R20 Geringhoff (all models except Freedom), Rigid and Folding |

Torsion Pivot |

1,132 lbs. |

|

5000-046C-GER |

12-Row |

12R22 Geringhoff (all models except Freedom) |

Torsion Pivot |

737 lbs. |

|

5000-047C-GER |

18-Row |

18R22 Geringhoff (all models except Freedom), Rigid and Folding |

Torsion Pivot |

1,177 lbs. |

|

GLEANER |

||||

|

5000-023C^ |

6-Row |

Gleaner 3000 or Hugger 630 (1988 and newer) |

Compression Spring |

767 lbs. |

|

5000-024C^ |

8-Row |

Gleaner 3000 or Hugger 830 (1988 and newer) |

Compression Spring |

1,047 lbs. |

|

5000-035A^ |

8-Row |

3308, AGCO |

Compression Spring |

1,022 lbs. |

|

5000-039^ |

12-Row |

3312, AGCO |

Compression Spring |

1,293 lbs. |

|

JOHN DEERE |

||||

|

5000-026E* |

8-Row |

843/893 |

Compression Spring |

932 lbs. |

|

5000-027E* |

12-Row |

1243/1293 |

Compression Spring |

1,382 lbs. |

|

5000-040E# |

6-Row |

606C/706C/C6R STALKMASTER™ |

Torsion Pivot |

532 lbs. |

|

5000-041E# |

8-Row |

608C/708C/C8R STALKMASTER™ |

Torsion Pivot |

682 lbs. |

|

+5000-042E# |

12-Row |

612C/712C/C12R/1290 STALKMASTER™ |

Torsion Pivot |

722 lbs. |

|

5000-044E# |

12-Row |

612C/712C/C12R STALKMASTER™, Rigid and Folding |

Torsion Pivot |

932 lbs. |

|

5000-045E# |

18-Row |

618C/718C/C18R STALKMASTER™, Rigid and Folding |

Torsion Pivot |

982 lbs. |

|

5000-046E# |

12-Row |

612C/712C/C12R STALKMASTER™ |

Torsion Pivot |

707 lbs. |

|

5000-047E# |

18-Row |

618C/718C/C18R STALKMASTER™, Rigid and Folding |

Torsion Pivot |

1,027 lbs. |

|

5000-048B |

8-Row |

608C/708F/C8F, Folding |

Torsion Pivot |

840 lbs. |

|

5000-014E & -048D |

16-Row |

Deere C16F Folding (REQUIRES THE TWO KITS) |

Torsion Pivot |

1,522 lbs. |

|

5000-091 |

6-Row |

644/694/606/706/C6R (Wide) |

Torsion Pivot |

618 lbs. |

|

5000-092 |

8-Row |

844/894/608/708/C8R (Wide) |

Torsion Pivot |

824 lbs. |

|

5000-093 |

12-Row |

1244/1294/612/712/C12R (Wide) |

Torsion Pivot |

1,236 lbs. |

|

MASSEY FERGUSON |

||||

|

5000-023C^ |

6-Row |

3000 (1988 and newer) |

Compression Spring |

767 lbs. |

|

5000-024C^ |

8-Row |

3000 (1988 and newer) |

Compression Spring |

1,047 lbs. |

|

NEW HOLLAND |

||||

|

5000-009C^ |

6-Row |

96C/98C/996 |

Compression Spring |

682 lbs. |

|

5000-005B^ |

6-Row |

98D |

Compression Spring |

657 lbs. |

|

5000-029B^ |

6-Row |

980CR |

Compression Spring |

682 lbs. |

|

5000-006C^ |

8-Row |

98D |

Compression Spring |

960 lbs. |

|

5000-010C^ |

8-Row |

96C/98C/996 |

Compression Spring |

922 lbs. |

|

5000-019C^ |

12-Row |

98C/98D/996 |

Compression Spring |

1,317 lbs. |

|

5000-032C^ |

12-Row |

980, Rigid & Folding |

Compression Spring |

1,357 lbs. |

|

5000-042D-CNH |

12-Row |

96C/996/98D, Rigid Corn Metering |

Torsion Pivot |

725 lbs. |

|

5000-046D-CNH |

12-Row |

96C/996/98D, Rigid |

Torsion Pivot |

650 lbs. |

|

5000-060E |

6-Row |

99C/980CR Chopping, Rigid |

Torsion Pivot |

490 lbs. |

|

5000-061E |

8-Row |

99C/980CR Chopping, Rigid |

Torsion Pivot |

652 lbs. |

|

5000-062E |

12-Row |

99C/980CF/980CR Chopping, Rigid and Folding |

Torsion Pivot |

932 lbs. |

|

5000-063E |

12-Row |

9212 Chopping, Rigid |

Torsion Pivot |

722 lbs. |

^ 5000-080 Extension Kit for use with chopping rolls, John Deere RowMax, Calmer BT, Geringhoff XDC, or 360 CHAINROLLS. Moves location of rollers back 5" (requires two per roller). Order for John Deere 5000-025 through -034 Kits prior to model year 2024 and for the above models noted with ^. Call Yetter Sales Department at 800.447.5777 with questions.

* 2024 model year & newer Deere spring kits do not use and are not compatible with the 5000-080 extension kit.

+ If ordering for a 1290, must order 6) 5000-070 adapter kits

# Can be used with Calmer or Claas

Call Yetter Sales Department at 800.447.5777 with questions about compatability for makes or models not listed.

5000-080, 5000-081, 5000-082, 5000-083 and 5000-084 Accessory Kits

5000 Stalk Devastator- Various Models for Case IH, John Deere, Drago & Geringhoff

Case IH installation video

John Deere installation video

Stalk Roller for 12-Row Lexion C512-30 and C508-30 Corn Head

Corn Stalk Roller for 6- & 8-Row Gleaner 3000/3308 or Hugger 630/830 MF 3000 (1988 & newer)/Challenger CH630/830 Corn Head

John Deere Corn Head Models 643, 693, 606C, 612C (wheel tracks), 608C (2012 & Newer), 612C, & 616C

John Deere Corn Head Models 643, 693, 606C, 612C (wheel tracks), 608C (2012 & Newer), 612C, & 616C

Fits models 4406 or 4408 Rigid and Folding or 4412 Case IH/ New Holland 980CR Corn Heads

Corn Stalk Roller for 6-, 8-, 12-, & 18-Row John Deere 606C/706C, 608C/708C, 612C/712C, 618C/718C Stalkmasters & 1290 Corn Heads; Geringhoff Chopping/20",22" & 30"; Case 2212/ 2412/3212/3412; New Holland NH96C/996/98D; Calmer /Lexion and Capello Non-Chopping

Installation video - short

Installation video - extended

Corn Stalk Roller for 6-, 8-, 12-, 16-,& 18-Row Drago GT Corn Heads

Corn Stalk Roller for 6-, 8-, & 12-Row Case IH, New Holland Corn Head

5" Extension Kit for Devastator

2" Lift Kit for Devastator

Single Row Devastator

Cover Crop Roller Attachment

"I stand by #yetter #devastators Great product

"

"Our operation is a small family farm. We do some continuous corn, and we tend to cut high to leave as much of the stalk as we can. We had a 9450 combine that we loved, and we had the Devastators on the 693. Easiest trips we've ever made! It shattered the stalk, then we had some rainfall on it. We came back in a couple weeks and it was amazing. We just loved it.

With the current hybrids, we're producing more and more yield, right? So there's just so much more plant material we have to manage on the back end. One way [to do that] is getting in early, cracking those stalks open, allowing it to get weather, then water, and then coming back and shattering it, and then we allow it to go right into strips. … We do as much as we possibly can to break it down now. It just allows us to be very efficient with our time.

"[Then] we went from a 12-row planter to a 16-row planter, which changes your head. The corn head that we got had Stalk Stompers on it, which we've had some experience with. But we like the results of the Devastator [we had two] so much more than we had with the Stompers that we ended up buying another Devastator, the middle one."

“New hybrid stalks simply do not decompose like stalks used to. We tried stomper-style attachments and were completely disappointed—there was no measurable success at all. Then about seven years ago, we switched to the Yetter 5000 Stalk Devastator and saw complete tire protection for all equipment entering the field, as well as much better stalk decomposition.

“When the time came to upgrade corn heads, we knew no matter what corn head we ended up with, it would definitely be equipped with Devastators!”

“I first started using Yetter Stalk Devastators in 2017 on a John Deere 8-row corn head. Using them, we have been able to no-till into cornstalks and have no more tire damage from Bt variety stalks. The Devastators work so well that I will not go to shell corn without them.”

"The Yetter 5000 Stalk Devastator™ we have on our Drago corn head not only saves the tires on our equipment, it provides better residue breakdown. The Devastator performs better than our old stalk stompers at getting the stalks cracked and in touch with the ground. It has improved planting conditions for our no-till beans and strip-till corn-on-corn.

"The Devastator has also proven very durable compared to our previous stalk stompers. And the rollers were easy to install—it took two people just a couple hours to complete."

https://twitter.com/tyoung_5/status/907988463772999680?refsrc=email&s=11

https://twitter.com/eriebfarms/status/913540264270147584?refsrc=email&s=11

https://twitter.com/dfarms001/status/920646625592315904?refsrc=email&s=11

https://twitter.com/cgovier/status/921064309962170368?refsrc=email&s=11

https://twitter.com/seuntjensfarms/status/920716641867939840?refsrc=email&s=11

https://twitter.com/precisionbaker/status/924412445975867392?refsrc=email&s=11

https://twitter.com/dfarms001/status/924265740320075776?refsrc=email&s=11

Jim Ries used a chopping corn head for several years and was not impressed with the performance. Jim found that the chopping corn head required high maintenance and in-season costs, which led to downtime for repairs.

For the fall of 2014, Jim purchased the Yetter 5000 Stalk Devastator™ for his John Deere 612 12-row 30" conventional corn head. Impressed by the condition of the field after harvest and that the stalks did not blow around like they did when he used the chopping corn head, Jim is pleased with the Yetter setup compared to his previous setup.

"It’s the best purchase we made this year," said Matt Blankenship of Pioneer Seed & Blankenship Farms, referring to the Yetter 5000 Stalk Devastator™. "Today’s corn stalks are so much tougher, but the Devastator was the answer I was looking for to plant into corn stalks."

Matt had previous experience with several types of stalk stompers on his approximately 2,200 acres of corn, but this equipment never lasted more than one season before issues or problems arouse. "I was on the market for something better," he said. When he first contacted Yetter, they didn’t have a Devastator that would fit his Geringhoff folding 12-row corn head, but Matt’s sales representative worked with him to help figure out a solution.

Matt also appreciates that the Devastator saves him money. "Tractor tires are so expensive. A couple years ago, I no-tilled soybeans into standing corn stalks and ruined a set of tires. With the Devastator, stubble damage on my tires is non-existent. The stalks are so bent over so there’s no way they could hurt the tires. The Devastator has worked so well it’s hard to believe anything could be better."

Yetter now offers Devastator models for 6-, 8-, and 12-row Geringhoff, Drago, Claas/Lexion, and AGCO/Gleaner/Challenger/Massey-Ferguson.

Next year, Mike Cline will be running Yetter 5000 Stalk Devastators™ on all three of his John Deere S680 12-row combines. They’ll cover 6,500 corn-on-corn acres, successfully knocking down stubble and preventing tire damage. "We really started seeing problems with premature tire damage—after only a year or two, our primary tillage tractors needed new tires," Mike said. "The stalks are stiffer today, and we are combining a little early so the corn is greener.

"My Case IH dealer recommended the Devastators to me last year. We used them on two combines and they worked really great. The stalks lay down nicely; I got out and checked, and they were broken in a few places, so they stayed down. That helped with breakdown—the residue flowed easier when we made our tillage pass with the disc ripper, and we also had more breakdown over the winter.

"The Devastators installed really easily—after the first roller was on, we got both combines done in less than an hour and a half. I was worried they would be hard to get on the header carts, but that was easy, too—much better than other ski-style rollers I have tried."

David Dimmich and his son, Zachary, purchased a Yetter 5000 Stalk Devastator™ for use during fall harvest on their farm in Indiana, about 100 miles south of Chicago. They plant no-till soybeans after corn and had frequently experienced problems with tire damage from standing stalks after harvest. The stalks also make it difficult to plant no-till soybeans the following spring.

"We didn’t want to buy equipment that would chop up the stalks and allow them to blow during winter and wash into low areas," said David. "We wanted something to condition the fields, but not cut or tear out the stalks. In that regard, we were elated with the Devastator’s performance."

David reports that the Stalk Devastator took very little time to prepare for transport. They made a few minor adjustments to mount it on their John Deere 1293 corn head, but now the Stalk Devastator fits very well.

David and Zachary received many comments from other farmers in the surrounding area who liked what they saw. "We’ll need to wait for the spring planting to say for sure, but the stalks were rolled down tightly without being dislodged, which we hope will make for less tire damage and easier planting next spring."

Like many farmers, Dave Hunt has been plagued with stubble damage to his tires. He has faced this challenge with a new tool at his side—the Yetter 5000 Stalk Devastator™.

With the Devastator mounted on his eight-row corn head, Dave rolled and crushed 1,500 acres of strip-till cornstalks. "We felt like it was a good improvement over the traditional stalk stompers," said Dave. "It prepared a better seedbed for our strip-till corn-on-corn. It left the field looking very good."

He also felt it effectively preserved the residue cover: "We didn’t have any problems with stalks blowing, and we heard that can be a problem with some competitive products. It is a very well-made product."

For harvest, Mike France used the 5000 Stalk Devastator™ attached to his corn head to knock over and crush corn stalks, testing its effectiveness for Yetter. "When Yetter came at the end of the harvest to take it off, I told them I wanted it back!" said Mike.

For his 2,200 acres of strip-till corn, Mike had previously used stalk stompers on his corn head to save the rear tires on his combine, but they only knocked down some of the rows, leaving others to damage his tires. The Stalk Devastator, however, knocked down all the rows. "It did a really nice job of laying the stalks over, crushing them, and starting the decay process,” explained Mike. “I saw the difference in the field in the spring." And while in the course of the previous year he ruined a set of tires on his tractor, this year he saw no more than normal wear.

He also says that the Stalk Devastator fit easily into his harvest schedule. "Running the Stalk Devastator caused no delays or inconvenience at all."

The 5000 Stalk Devastator can be installed on most corn head models. Once installed on the corn head, the Stalk Devastator will also fit on the majority of head cart makes and models. Some modifications may be necessary to ensure a proper fit. Choose your combine head width below and view some examples of the Stalk Devastator/head cart compatibility.

Our sales and support team are here to answer any questions you have about installing the Devastator and transporting it on your specific head cart make and model.

Unverferth HT25 | John Deere 608C

EZ Trail 672 | John Deere 893

EZ Trail 680 | Case IH 2208

EZ Trail 680 | Case IH 2208

EZ Trail 680 | Case IH 2208

Unverferth HT25 | John Deere 608C

Unverferth HT25 | John Deere 608C

Drago GT 8R30 | Horst CHCF36 (Torsion Mount)

Unverferth HT30 | John Deere 612C

Unverferth 530 | John Deere 612C

Unverferth HT30 | Drago Series II

B B | Claas 12-30

Unverferth HT 30 | John Deere 612 C

Unverferth HT 30 | John Deere 612 C

EZ Trail High Speed | Lexion Head

EZ Trail High Speed | Lexion Head

Woodworth 32' | John Deere 612C

Maurer M32 | John Deere 612

Unverferth HT 30 | John Deere 612 C

Yetter 32' | John Deere 712 FC

Yetter 32' | John Deere 712 FC

Yetter 32' | John Deere 712 FC

Yetter 32' | John Deere 712 FC

Maurer M42 | John Deere 716C

Maurer M42 | John Deere 716C

Yetter 38' | Case IH 4412

Yetter 38' | Case IH 4412

Yetter 38' | Case IH 4412

Hello from YetterCo.com! This website uses cookies.

We use cookies to continuously improve our services and visitor experience. Additionally, we set cookies for visitors on social media sites to track performance. By continuing on this website or clicking "Ok" we will assume that you have read this information and consent to receive cookies on our website. For more information visit our website's Privacy Policy.