Since its introduction, the Twister Closing Wheel has received positive feedback. In Beck’s Practical Farm Research studies, the Twister increased yields by an average of 5.1 bushels per acre.*

Beck’s PFR provides unbiased, farmer-focused research through studies conducted across the Midwest. A Beck's PFR Proven product or practice provides a positive yield increase during three or more years of testing. Products must average a positive return on investment during that time. The studies compared the Twister Closing Wheel with other closing wheels on the market.

*Please remember yield results vary based on many factors each year. Always consider your unique operation when deciding what equipment to invest in. Data found here is only a starting point.

If you’re rolling the dice with factory rubber closing wheels, or leaving it up to the weather Mother Nature sends your way, you’re missing an opportunity to maximize yield.

Poor seed-to-soil contact is a major cause of uneven emergence, a problem that can result in yield loss. Factory rubber closing wheels are designed to firm up loose soil—but they do nothing to fracture sidewall compaction or ensure seeds are fully surrounded by soil.

To close the seed furrow and set your crop up for even emergence, equip your planter with Yetter Twister Closing Wheels. The Twister is a cost-effective, high-performing replacement closing wheel that provides ROI. The most effective setup is to run your Twisters in pairs on each row (left and right).

As a general starting point, we recommend spacing your Twister Closing Wheels at 1 1/4" to 1 1/2". Then evaluate your field conditions, soil type, and tillage practices—you may want to adjust the spacing to ensure you are properly breaking through the sidewall and creating optimal seed-to-soil contact.

Here’s how to check whether you need a better closing wheel:

With the Twister Closing Wheel, the seed furrow is closed, giving you assurance that the investment you made in seed, chemical, fertilizer, and equipment will produce the yields you have planned for.

Crumbles and firms soil simultaneously: Twisted spikes enhance seed-to-soil contact and help create the ideal seed environment, leading to even crop emergence and higher yields. The rounded center ring—sized 12" to match the size of rubber closing wheels—maintains consistent depth.

Works in diverse field conditions, cover crops, and tillage practices: Optimize performance for minimum-till, conventional, strip-till, vertical tillage, or no-till by adjusting down pressure on the tail wheel closing arm.

Fractures the sidewall: In wet, unfavorable planting conditions, the Twister fractures the sidewall. This reduces the potential for crusting and the seed furrow drying out and cracking open.

Prevents mud buildup: A smooth surface and a rounded center design help prevent problematic mud buildup, which can interfere with seed furrow closure.

Cost-effective and easy to install: The Twister Poly Closing Wheel is built for durability with ultra-high molecular weight (UHMW) plastic. It takes as little as five minutes per row unit to install. Independent studies by Beck’s Practical Farm Research have shown the Twister provides a positive return on investment.

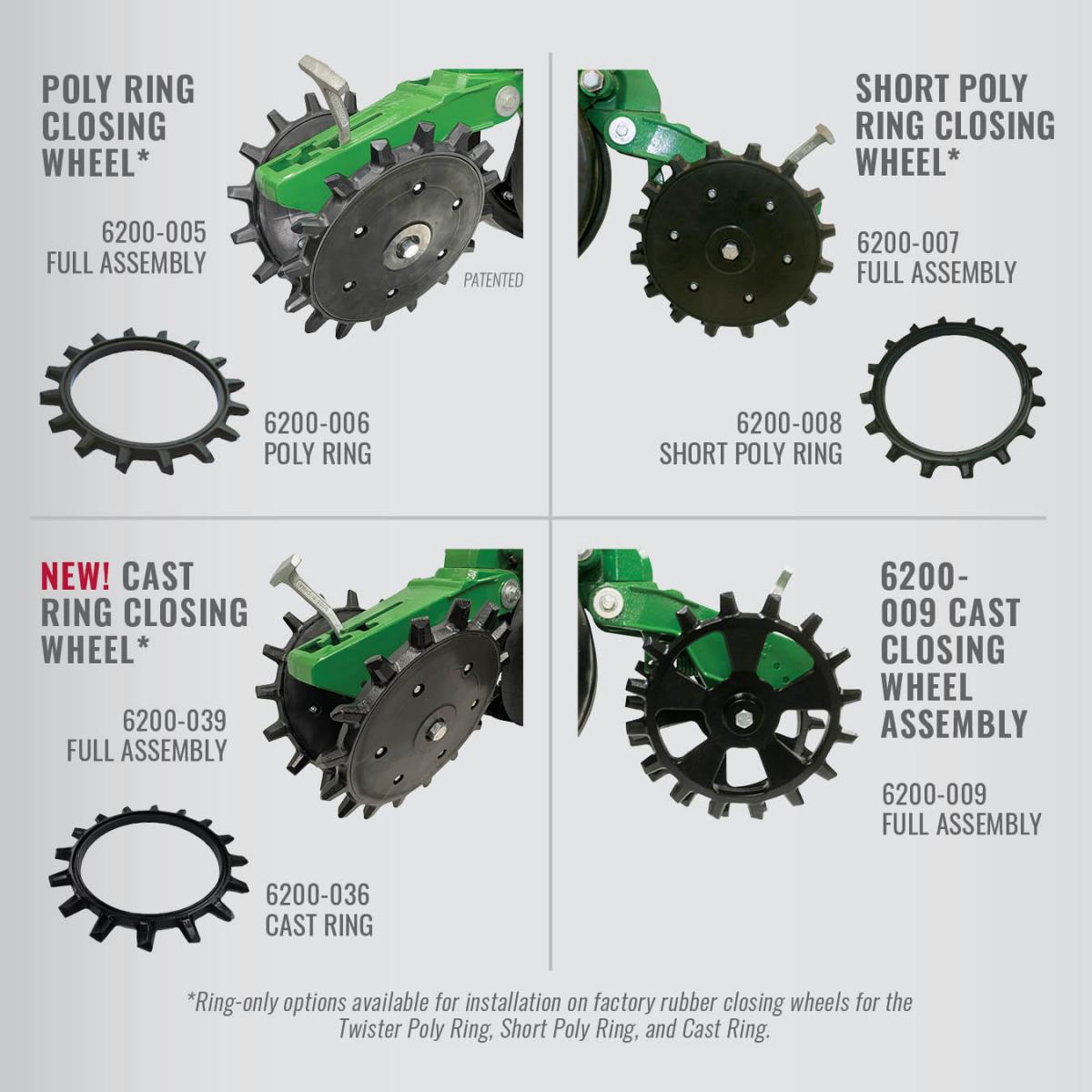

Setup options:

Compatible with:

Steve Pitstick, IL

READ MORE TESTIMONIALS